At Miller Electric, we’re always looking for ways to work smarter, safer and more efficiently.

Our emphasis on prefabrication is just one way we’re embracing the future — a smarter approach to electrical work that benefits both our workforce and our partners in the industry.

Prefab allows us to build components off-site in a controlled environment before they’re installed in the field. This method is great for the electrical industry: enhancing productivity, reducing installation times and improving job site conditions. But beyond operational efficiency, prefab is a game-changer for workforce development, mentorship and project consistency.

Less Chaos, More Control

Job site conditions can be unpredictable. Crowded spaces, shifting schedules and weather delays can disrupt even the best-laid plans. Prefabrication mitigates these challenges by shifting a significant portion of the work to a controlled environment where precision, quality and efficiency take center stage.

“We streamline the process by preparing materials before they ever reach the job site,” says General Foreman Steve Neal. That means less wasted time, fewer obstacles and more reliable project timelines.

By reducing the need for complex on-site assembly, projects move faster with fewer disruptions — benefits that resonate with general contractors looking for dependable project partners.

A Smarter Approach to Workforce Development

The advantages of prefabrication go beyond efficiency. It serves as a perfect training ground for the next generation of electricians. Our experienced tradespeople mentor apprentices and construction wiremen, offering hands-on learning opportunities that accelerate skill development.

“Miller uses seasoned electricians to pass down their knowledge,” Neal adds. “That mentorship is essential to maintaining a highly skilled workforce.”

This means working with a team that’s not only skilled but also well-trained in the latest industry innovations and best practices.

Scaling Up with Innovation

Since launching in 2013, Miller Electric’s prefabrication department has continually evolved to meet the growing demands of the industry. Led by Pre-Fabrication Operations Manager Chris Nightser, the department has adopted an assembly-line approach, increasing efficiency and precision.

“We’ve even developed ‘prefab for prefab,’” Nightser explains. “By cutting materials and completing preliminary steps ahead of time within the shop itself, we accelerate our workflows and boost overall project efficiency.”

This approach mirrors the efficiency of early automotive production lines, where systematic improvements led to faster turnaround times without sacrificing quality. By continuously refining our processes, projects stay on track while maintaining the highest standards.

Innovating Beyond the Blueprint

At Miller Electric, prefabrication isn’t just about efficiency — it’s about solving problems creatively. From large-scale industrial projects to unique custom lighting solutions, our prefab team thrives on tackling challenges that require innovation.

“One of my favorite projects involved designing lighting solutions for the Henry Doorly Zoo,” Nightser recalls. “It showcased our ability to think outside the box, engineering solutions for applications that don’t exist off the shelf.”

Building a Culture of Excellence

The strength of Miller Electric lies in our people. Prefabrication fosters a culture of collaboration and shared learning that translates into a stronger workforce and better project outcomes.

Keelon Rigby, a fifth-year apprentice, values the mentorship he’s received. “From day one, I had people willing to teach me everything,” he says. “It’s given me the ability to problem-solve quickly and apply that knowledge across all aspects of life.” He’s just earned his licenses in Nebraska and Iowa, well on his way to journeyman.

Construction Wireman Aidan Kidder also appreciates the sense of community. “There’s a real sense of teamwork here. Everyone’s working toward a common goal.”

What’s Next for Prefabrication?

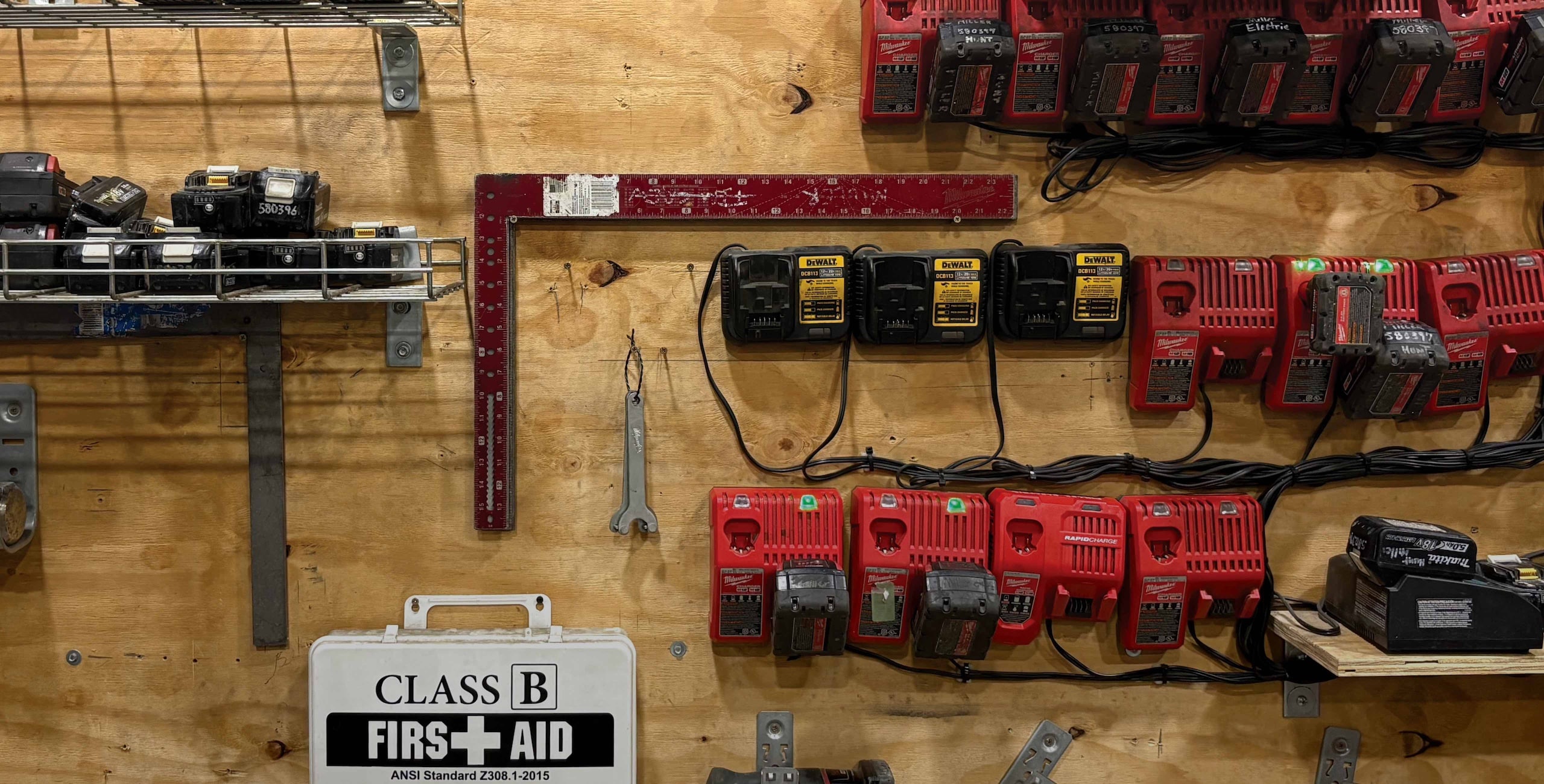

As Miller Electric continues to grow, so does our commitment to innovation in prefabrication. Over the years, we’ve transitioned from handheld tools to commercial-grade equipment that increases our capacity and speed. This evolution reflects a broader industry trend: the need to do more with less while maintaining the highest standards of quality and safety.

Miller Electric’s prefabrication expertise offers a tangible advantage. Faster timelines, improved safety and a skilled workforce — these aren’t just benefits for us, they’re advantages for every project we touch. That’s how we like it.